How we work

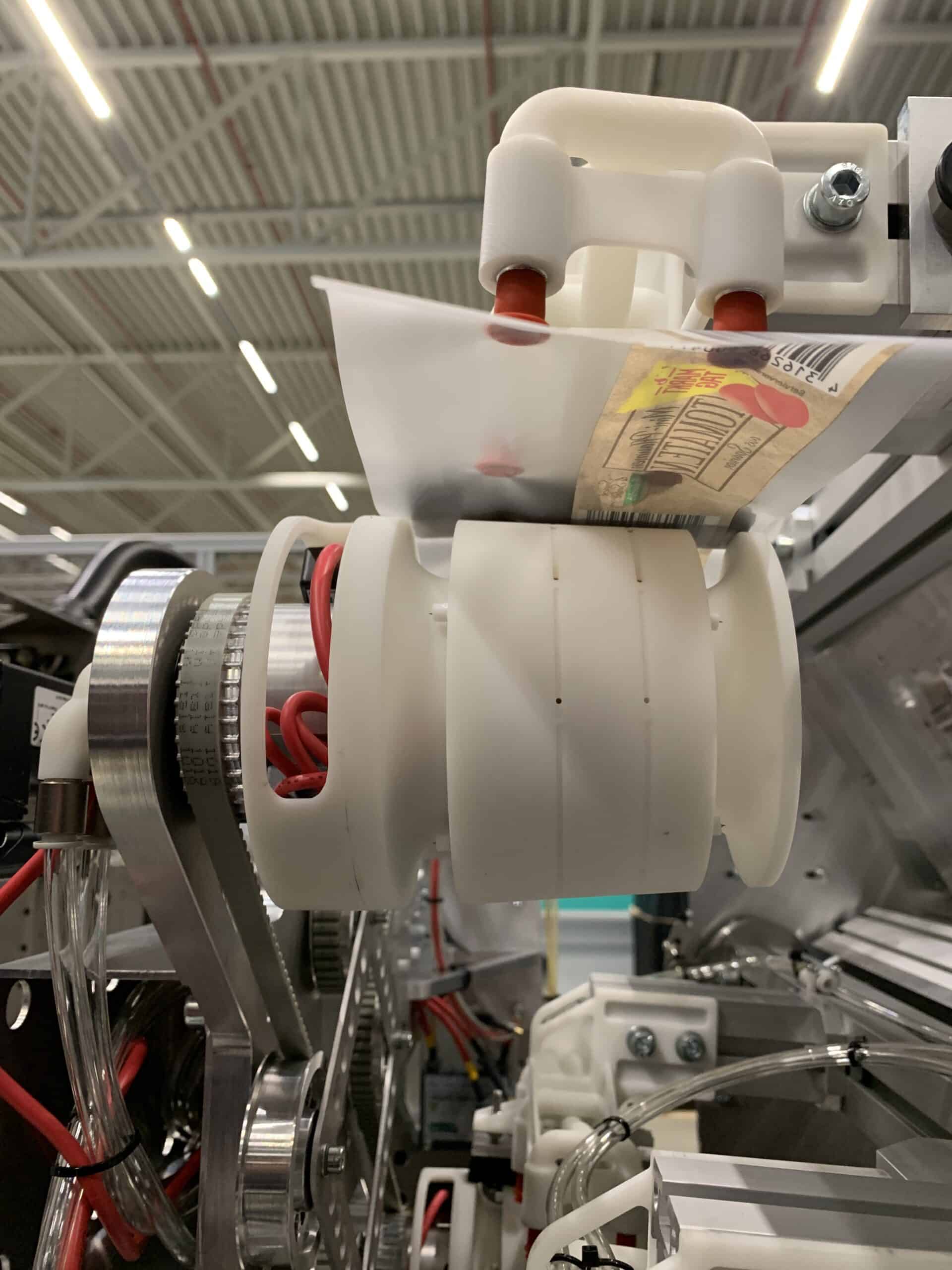

At Ronetic, we take an expertise-driven approach to machine building and industrial automation. We analyse your needs, develop custom solutions with advanced technologies, and provide continuous support for long-term success. Together, we strive for optimal efficiency and performance in automation.

Our approach